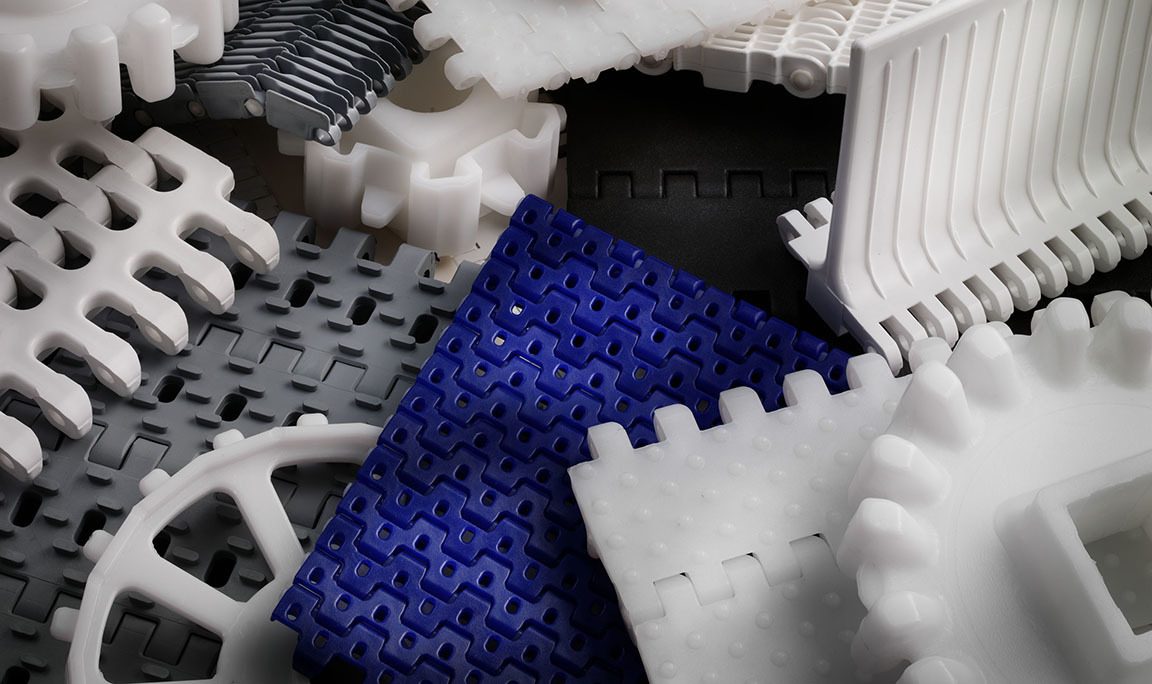

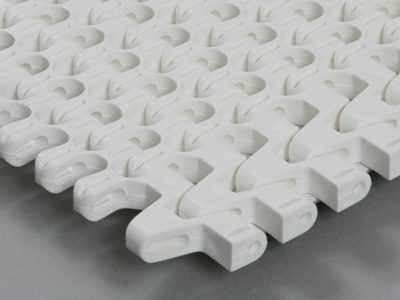

Dura●Lock Modular Plastic Belting

Dura-Lock modular plastic belting from Sparks Belting is all about performance, endurance, cleanability, and fast, easy maintenance. It offers a versatile and durable solution to any problem in any industry.

The expertise to know how to do modular and do it right.

Sparks' technical experts have the experience to fit the right modular plastic belt to your company's needs whether it be seafood processing, baked goods, poultry processing, produce processing, wood, glass, raw materials, or more.

Dura-Lock modular plastic belting from Sparks can also be used for extreme applications, such as:

- Heat from ovens

- Cold from freezers

- High-pressure wash downs

- Drainage from vegetable, meat, poultry, and seafood processing

- Heavy automotive component lines

Sparks offers a wide range of special materials.

In order to solve out-of-the-ordinary problems, we offer a variety of special materials and additives.

- Materials for High-Temperature Areas

- Reinforced Materials

- Electrical Conductivity

- Non-Stick Materials

- Detectable Polypropylene

- Flame Retardant Materials

Standard materials in stock.

Sparks Belting works with ScanBelt to provide all of the traditional materials for modular plastic belts: Polyethylene, Polypropylene, and Polyacetal. All standard materials are FDA approved for direct food contact.

Standard Belt Compounds Offered:

- Polyethylene (PE): Ideal for cold areas or applications that require strong but flexible belts

- Polypropylene (PP): Ideal for high-temperature ranges

- Polyacetal (POM): Ideal for applications needing low friction. Great for bottling and canning.

- Custom compounds for temperature, tensile strength, friction, chemical resistance, and other special characteristics

See the whole Dura●Lock product line.

S.06 – 6.25mm pitch (.25")

Smallest pitch in the market and therefore able to obtain very small transfers. Runs on nose bars down to 7 mm. Easy to clean. Bakery and seafood industry for cooling/ freezing, dairy production.

Learn More

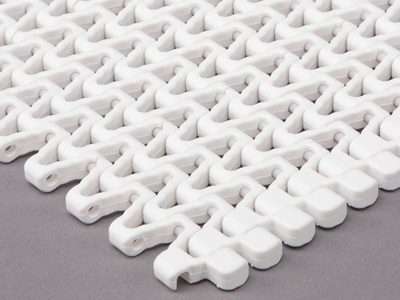

S.12 – 12.5 mm pitch (.49")

A true MINIPITCH with a 12.5 mm pitch. Designed for light transport. It is able to go around a 14 mm nose bar for very tight transfers. The placement of sprockets is flexible across the belt width, i.e. no risk of assembling or installation mistakes. The links are designed with open rod access and are consequently very easy to clean. They can be delivered with flights and rubber top surface.

Learn More

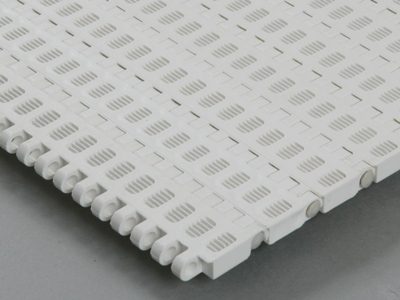

S.25 – 25 mm pitch (0.98")

The S.25 is a range of 25 mm pitch belts designed to solve all aspects of light to medium transport. The series consists of 17 belt types with distinct characteristics when it comes to open area and surface structure. Closed and open belts with a smooth or structured surface. Raised ribs and rubber surface. Belts with very good cleanability for the meat and poultry industry.

Learn More

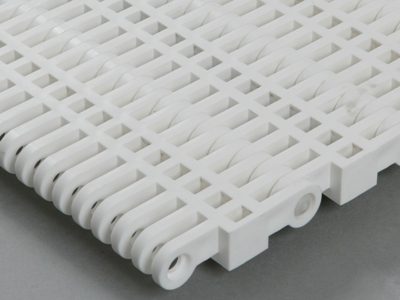

S.50 – 50 mm pitch (1.97")

The S.50 series is a range of 50 mm belts designed for medium to heavy transport. The series consists of 19 types of belts with different surface structures and openings as well as a complete range of easy-to-clean belts for high-hygiene applications. Rubber surface and different nub top structures for good product grip. The series contains a vast span of pulling forces from light cooling belts to heavy-duty belts for car and pallet handling.

Learn More

S.75 – 75 mm pitch (2.95")

The S. 75 series is a range of 75 mm pitch belts designed for super-heavy transport. The very high pulling force now makes it possible to make longer conveyors than previously possible. It is available with both smooth as well as non-skid surface as well as accessories, such as integrated side guards and comb flights.

Learn More

Radius Belt

25 years in the spiral and radius belt business has resulted in a range of 25 and 50-mm pitch belts going in J-curves and S-curves. The belts have a market-low collapse factor (from 1,5:1 x belt width) without compromising the pulling force and product placement. The reinforced outer links give a very high pulling force without any steel-to-steel contact.

Learn MoreLet an experienced Sparks Dura●Lock technical expert provide you with innovative application solutions.

Contact Us