Sparks

Belting motorized pulleys are supplied with press-fit or bolt-on end caps

for easier servicing. The housings are manufactured from seawater-resistant

aluminum or iron; 304 stainless steel is also available.

Shaft

Seal

Shaft

Seal

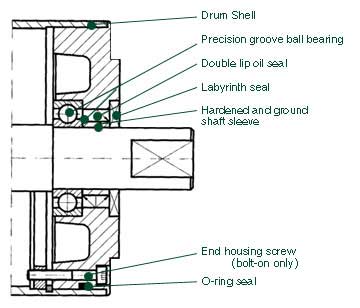

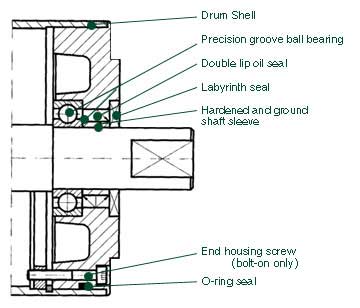

The end housings are fitted internally with double lip oil seals and

externally with steel labyrinth seals. This provides excellent protection

against ingress of dust, grit, water and moisture and even high-pressure

cleaning. The steel shafts are fitted with smooth precision wear sleeves

positioned under the double lip oil seals. This prevents wear to the

shaft and seals.

Protection

Class

All Sparks Belting motorized pulleys are protected to IP66 in accordance

with VDE0470 and therefore suitable for applications requiring high-pressure

washdowns. For special applications, protection class IP67 with stainless

steel re-greasable labyrinths is also available.

Shafts

Fixed and variable shafts are manufactured from mild steel and have

identical shaft diameters and shaft flats at both ends. 304 stainless

steel is optional.

Drum

Shell

The outer drum shell is manufactured from thick-walled mild steel tube

with a machined crowned face to ensure correct belt tracking. If desired,

a metal shell without crowning can be supplied. The drum shell is also

available in 304 stainless steel or, as a low-cost alternative, with

hard chrome surface.

Electric

Motor

All Sparks Belting motorized pulleys are designed to IEC standards in

accordance with DS 188 IV B1 and VDE 0530 with Insulation Class F standard

(Insulation Class H available upon request). The motor is an asynchronous

squirrel cage induction type. Class F motors are suitable for most applications

with ambient temperatures of +100°F -10°F. For temperatures

above or below this, Class H motors should be specified. In some cases,

Class H motors are recommended where the pulley will be working without

a belt or when fitted with very thick lagging. When in doubt, contact

Sparks Belting for recommendation.

Electric motors with windings for special voltages and frequencies

are available upon request.

Sparks Belting motorized pulleys are inverter duty motors and can

therefore have a stepless speed control in combination with static frequency

converters in the range from 30 to 60 Hz. For speed variations outside

this range, contact Sparks Belting.

Electrical

Connections

Standard motorized pulleys fitted with a terminal box can normally be

connected for single or dual voltage access.

Pulleys with fitted cables are normally supplied for one voltage only.

Dual voltage cable is available upon request at extra cost.

Transmission

Only two-stage and three-stage gear boxes are used. All gears are made

from high-grade steel which are hardened and polished. The belt speeds

given in the catalog are nominal. If exact speeds are required, contact

Sparks Belting.

Bearings

Only high-quality, single row or double row precision ball bearings

and needle bearings are used.

Casing

Parts

Gearbox, stator casing and rear flange are made of high-density aluminum

alloy. In high torque applications, ductile iron components are used.

Back

Stop

A backstop bearing can be placed in the drum motor to prevent product

roll back. This option is used primarily on inclined belt conveyors.

Thermal

Overload Protection

Sparks Belting motorized pulleys are equipped with thermal protection

(TF) in the stator of windings. This prevents motor failure due to overheating

or overloading. The TF will automatically re-set, but the motor must

be re-started manually. (Not available on 3.19" dia. pulley)

Cooling/Lubrication

The cooling of the electric motor and the lubrication of the transmission

parts and ball bearings is effected by means of SAE 90 gear oil. The

drum motor is factory oil-filled before delivery. For applications with

temperatures below -10°F or above 100°F, or when pulleys will

be used without a belt, contact Sparks Belting. Sparks Belting motorized

pulleys are designed principally for belt converyors. The angle between

the longitudinal axis of the pulley and the horizontal axis must not

exceed 5°. If it does, lubrication may be insufficient and damage

to the unit could occur. See Installation

& Maintenance for oil fill requirements and installation/maintenance

recommendations.

Rubber

Lagging

To achieve proper friction between the drum face and conveyor belt,

Sparks Belting offers lagging made of hot or cold-vulcanized 1/8", 1/4"

plain black or white, oil & fat resistant rubber, or hot vulcanized

rubber. Other types of materials (such as neoprene, silicone, pvc, etc.)

and patterns (such as diamond or grooved) are available.

Rubber lagging can cause thermal overload. To prevent this, the required

power should be multiplied by a factor of 1.2. Due to the increased

thickness of rubber lagging, the belt speed will increase accordingly.

Options

Overview

Back To Top

Shaft

Seal

Shaft

Seal