Pulley Configurator

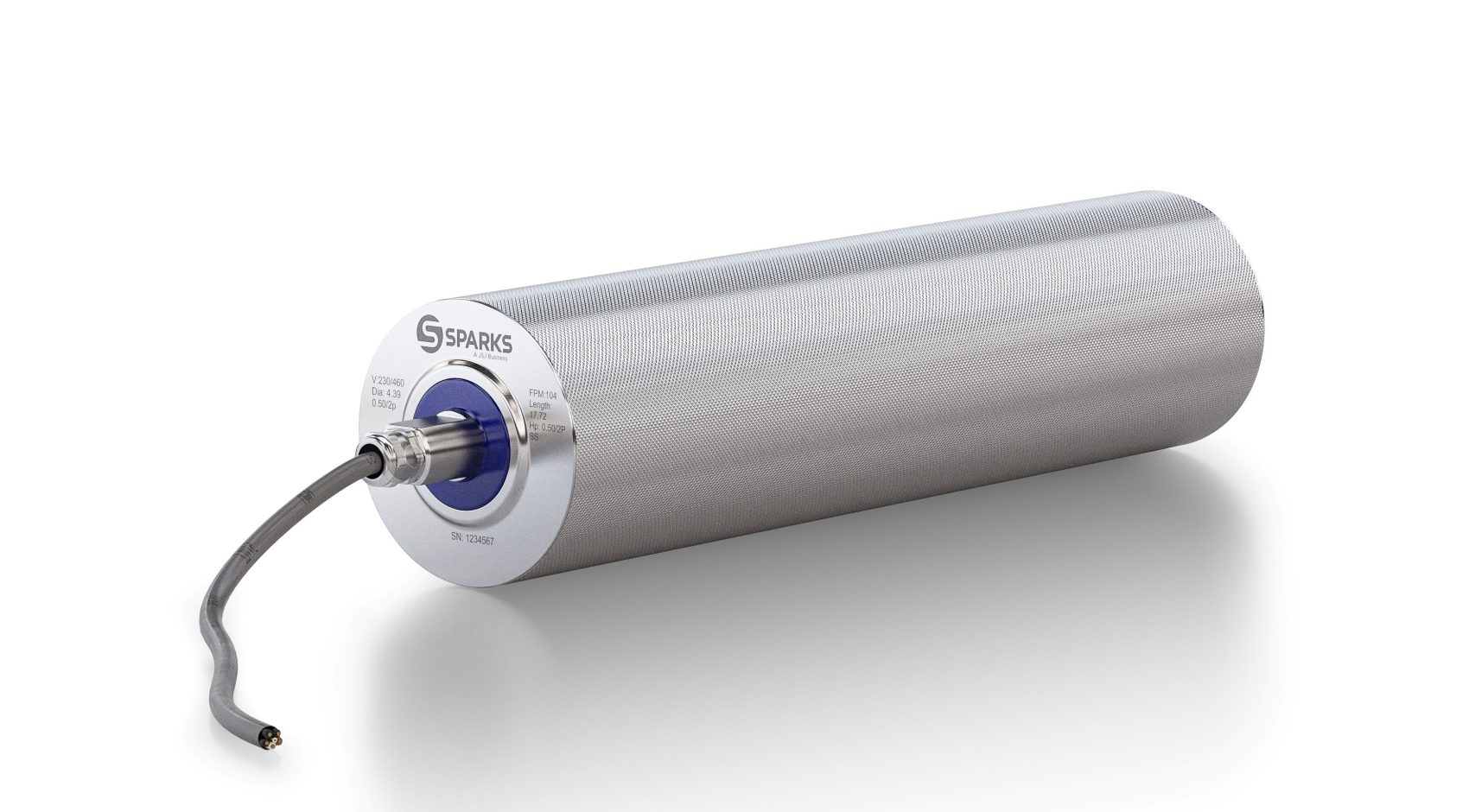

Our brand-new pulley configurator lets you design the pulley that fits your conveyance needs. You can download a 2D or 3D print instantly with our pulley configurator.

DISCLAIMER: Dura-Drive SPM pulley dimensions are different than Dura-Drive Plus. Please make sure you are selecting the correct product line when configuring your pulley.