Conveyor Belt Tensioning 101

Properly tensioning a conveyor belt is a critical step in tracking conveyor belts. Getting the correct amount of tension reduces splice failures, excessive stretch, and wear on the side of your frame. Luckily, there is a simple procedure to achieve the proper tension on a belt.

Step 1- Clean Conveyor & Install New Belt

The biggest nemesis to a conveyor belt working properly is contamination. Contamination most commonly comes in the form of product debris, worn pulley lagging, grease, and loose bolts inside of the conveyor frame. It’s critical when you remove your old belt to take the time to clean the frame. Once the conveyor is clean, it’s time to install the new belt.

Step 2- Pretension

After the new belt is installed it’s time to square all of your rollers and apply just enough tension to the belt so it moves once the motor is turned on. It’s crucial that everything remains square at this point and you are not attempting to steer the belt.

Step 3 – Careful Measurement

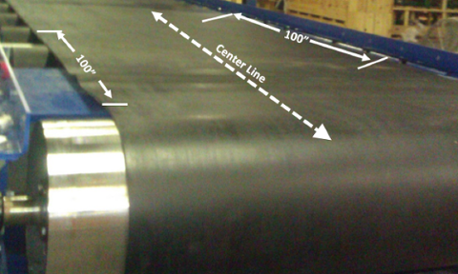

As your new belt lays flat on your conveyor bed, it’s time to make marks on each edge of the belt that are precisely 100” apart. These marks need to be perpendicular to the centerline of the belt. Be sure to take the time to double-check your measurements.

Next, apply gradual tension to your belt so that it conforms to your crowned drive roller. There should not be any slop between the belt and the pulley.

Measuring the distance between your marks as you tension your belt will provide you with the tension percentage of your belt. For instance, if the belt stretches to 100.5”-there is now .5% tension on the belt. Consult your belting supplier for the recommended tension on each belt.

PRO TIP: You can make the machine a jig to expedite this process and eliminate the errors of reading a tape measure.

Step 4 – Track Your Belt

Once your belt has the proper tension it’s time to steer it so that it doesn’t rub on the side of your frame and stays centered on the pulleys. Use the friction on the conveyor’s adjustment rollers to guide your belt as opposed to applying more and more tension. For instance, lessening the tension on your tail roll is equally as effective in steering your belt as adding more tension.

Pro Tip: Over-tensioning your belt will lead to splice failures and tracking problems!

Always make sure that your conveyor belt has the proper tension in order to have accurate tracking. Both proper tension and proper tracking will ensure the life of your conveyor and lead to less downtime. Follow our easy 4-step belt tensioning process the next time you need to replace your conveyor.

All Blog Posts