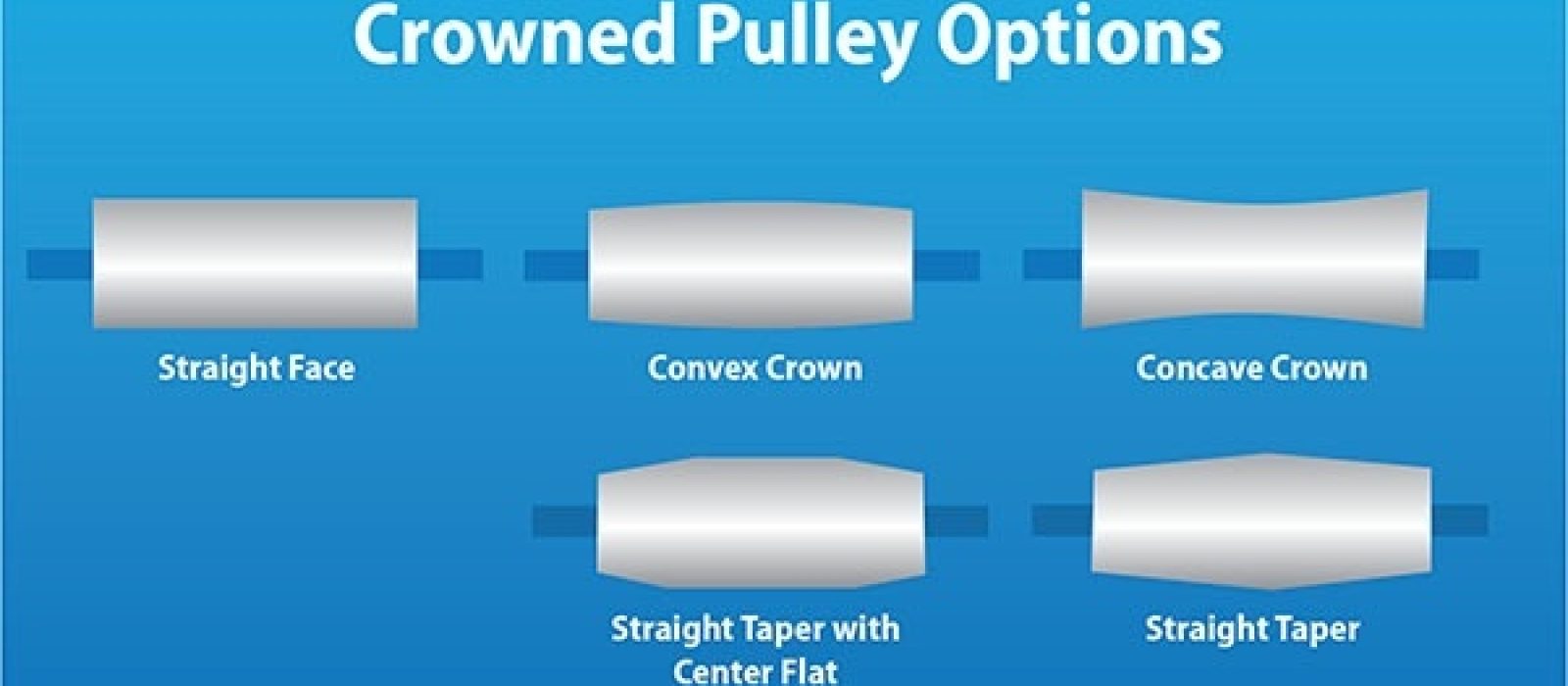

Crowned Pulleys — Which Option is Right for You?

The purpose of a crowned pulley (or tapered pulley) is to assist with belt tracking. In most operating conditions, a belt will follow the path of highest tension. So, it makes sense to have the diameter of the pulley larger in the center than at the edges.

Most often, conveyor systems that use a v-guide on the back surface of the belt are manufactured with straight-face pulleys. There is no need for pulleys to be crowned or tapered when a v-guide is used. A concave crown is seldom used unless there is a very special reason to do so. Even on troughed conveyors, flat face and crowned pulleys are generally used.

On pulleys with < 24” face width, some engineers prefer a convex crown pulley shape. Others prefer a straight taper with center flat. A convex crowned pulley usually has an increase of +/- 1/16” per foot of pulley width. Therefore, an 18” face width pulley (4” in diameter), could either have a 4” diameter measurement in the center with 3-13/16” diameter edges or a 4-3/32” diameter measurement in the center with 4” diameter edges.

On pulleys with > 24” face width, most engineers prefer a straight taper pulley with center flat.

Q: On a straight taper pulley with center flat, how much of the pulley face width is flat, and how much is tapered?

Up to 36” face width, the center third of the pulley width is flat. Then, one-third of the pulley is straight tapered to the left and right of the flat surface.

- 18” face width pulley would have a 6” flat face center, with (2) 6” straight tapered edges.

- 24” face width pulley would have an 8” flat face center, with (2) 8” tapered edges,

- 30” face width pulley would have a 10” flat face center and (2) 10” tapered edges.

When the pulley face with is ≥ 36”, the straight taper sections normally do not exceed 12”.

- 40” face width pulley would have a 16” flat face center, with (2) 12” tapered edges.

- 48” face width pulley would have a 24” flat face center, with (2) 12” tapered edges.

Q: Are both the drive pulley and idler pulley normally crowned?

YES, unless when used with a v-guide.

Q: How much taper is there on straight taper pulleys with center flat?

It depends somewhat on the diameter of the pulley. On 4” diameter pulleys, the taper is often less than 1/16” (.04” - .05”). On 6” diameter pulleys, the taper is often slightly more than 1/16” (.07” - .08”). This can vary based on the manufacturer. The transition from taper to flat must be smooth to avoid damaging the fabric or carcass of the conveyor belt.

For Dura-Drive Plus motorized pulleys, a straight taper with center-flat is provided.

All Blog Posts