Logistics and Warehouse Distribution

Sparks Belting works with industry leaders to provide an evolving offering of engineered materials designed to optimize performance.

Distribution centers rely on Sparks Belting to provide solutions that handle their demanding work load.

As sortation systems evolve and get more complex, they are engineered to increase throughput from their facilities to keep up with growing worldwide demand.

Sparks Belting provides a wide selection of conveyor belts, timing belts, and motorized pulleys to keep packages moving from your shelves to your trucks. The high speeds, gaping, merging, sorting, and incline applications that are common throughout your facilities are all opportunities to increase efficiency, reduce noise, decrease downtime, and save money.

NEW: Sparks OEM Replacement Curve Belts

More InformationLogistics and Warehouse Applications

Warehouse Distribution

- High-speed conveyors

- Merging and gapping

- Live roller conveyors

- Telescoping conveyors

- Quiet weave belting

- Splicing solutions

Airport

- Flame retardant

- Metal detector belts

- Incline conveyors

- Check-in

- Baggage claim

- Emergency service

Check Out Counter

- Large production runs

- High-frequency factory splices

- Non-stick and Non-marking cover

General Conveyance

- Packaging equipment

- Tape machines

- Check weighers

- Merging conveyors

- Accumulation tables

- Incline and decline

Power Turn Belting

- Urethane belt guides, roller chains, or bearings

- Industrial and food-grade options

- 45°, 90°, and 180° curves

- Spiral lift applications up to 720°

Value Added Solutions

- Inventory reduction

- Make and hold programs

- Documented cost savings

- Storeroom and plant surveys

- On-site training programs

- 24/7 Emergency service

We can handle even the toughest challenges.

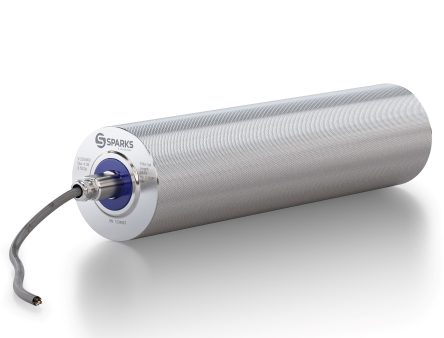

Motorized Pulleys

Sparks Dura Drive pulleys are an ideal solution to reduce energy consumption, reduce storeroom inventory of expensive motors and gearboxes, and provide a more compact and safer conveyor.

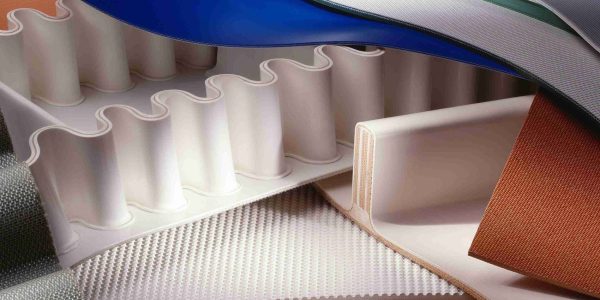

Belting Solutions

Distribution Centers offer several challenges and Sparks has a solution for every application. With over 200 materials in stock, we can help you address any of the following:

- Incline conveyors

- High speed sorting or indexing

- Belt tracking issues

- Turn belts

- APC belting

Lacing

High speeds, heavy loads, cameras, and small pulleys place unique demands on mechanical lacing. Sparks offers the correct lacing solution for your application. The Sparks Belting R&D team can determine the best lacing for each belt material and application in order to reduce your overall belting spend.

We combine high quality conveyor system engineering with superior service.

Custom Conveyor Belting and Fabrication

Over 200 standard materials in stock with custom belting available and years of experience supporting food grade and industrial OEM applications.

See All Belting

Dura-Lock Plastic Modular Belting

Our standard materials are FDA approved for direct food contact. Special materials and additives are available for challenging tasks.

Learn More

Dura-Drive PLUS Motorized Pulleys

Cost effective, energy efficient, highly sanitary, quiet operation with low maintenance due to its one piece construction. Guaranteed to power your belt conveyors for years.

Learn More

Dura-Tech Timing Belts

Urethane timing belts designed for linear motion, conveying, and power transmission applications.

Learn MoreStart optimizing performance, reducing downtime, and increasing efficiency with a new conveyor belt fine tuned to your warehouse.

1-800-451-4537