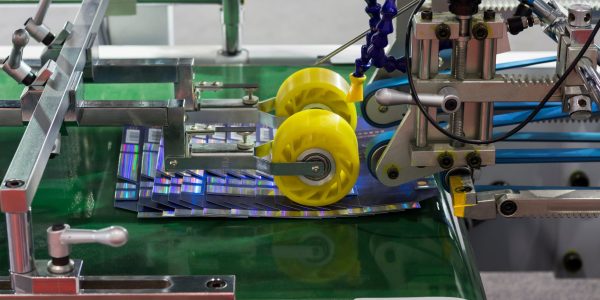

Paper and Print

We understand the demands and strain put on your conveyor belts and have proven solutions that guarantee increased belt life and less downtime.

The highly competitive paper and print industries rely on and trust Sparks Belting.

Your applications are demanding— our application specialist team at Sparks Belting is trained to provide industry-leading expertise throughout the paper and print industry. In order to keep you running safely and avoid unnecessary downtime, we bring the expertise and experience you need.

Sparks offers a wide range of belt covers and constructions which provide the ideal blend of grip and release for a corrugated or printed surface. Your goal of reducing installation time can be achieved with special constructions that have proven and documented success in your applications. Whether you are trying to reduce jam-ups, increase the life of your mechanical lacing, or reduce marking, Sparks Belting will provide you with solutions that will solve the most challenging problems.

Proven solutions that guarantee increased belt life and less downtime.

Paper and Corrugated Converting

- Product grip

- Lace retention

- Vacuum belts

- Tracking issues

- Wear resistance

- Round belting

Folder Gluer

- Nylon core

- Quick melt

- Splicing tools

- On-site splice training

- Installation support

- Specialty high-grip feed belt covers

Printing

- Tube winders

- Bookbinding

- Power turns

- Sheet feeders and layboy

- Cross-cutter and sheeters

- Timing belts

Coated Paperboard

- Non-marking belting

- Die cutting

- Feed belts

- Precise feeding and stacking

- Quick installation belts

- Non-marking lacing

Counter Ejector

- Strong lace retention

- High grip surfaces

- Easy to clean

- ZipLink belting

Folding Rails

- Vacuum strength

- Variety of low durometer surfaces

- Heavy-duty construction and superior hook strength

- High speed

We can handle even the toughest challenges.

Sparks sets the standard for on-site training.

- Quick melt splicing

- Ziplink

- Mechanical lacing

- V and round belt welding

- Belt tracking

We provide the tooling to get the job done quickly.

- Roller lacers

- Vulcanizers

- Hand-held presses

- Friction welders

- Belt clamps

- Lacing, skivers, and repair kits

Available whenever you are with 24/7 service & support every day.

With 12 locations in the U.S. and Mexico, Sparks is a national company with regional centers offering customers fast turnaround, large inventory selection, on-site installations, and support all delivered with exceptional service.

We combine high quality conveyor system engineering with superior service.

Custom Conveyor Belting and Fabrication

Over 200 standard materials in stock with custom belting available and years of experience supporting food grade and industrial OEM applications.

See All Belting

Dura-Lock Plastic Modular Belting

Our standard materials are FDA approved for direct food contact. Special materials and additives are available for challenging tasks.

Learn More

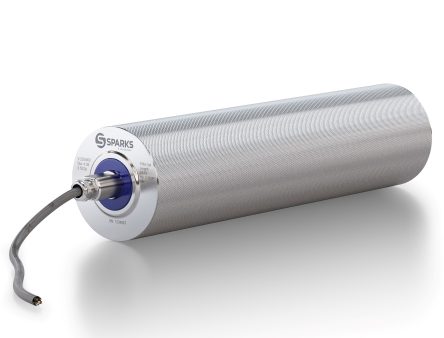

Dura-Drive PLUS Motorized Pulleys

Cost effective, energy efficient, highly sanitary, quiet operation with low maintenance due to its one piece construction. Guaranteed to power your belt conveyors for years.

Learn More

Dura-Tech Timing Belts

Urethane timing belts designed for linear motion, conveying and power transmission applications.

Learn MoreDo you want to increase your belt life and decrease downtime? We can show you how.

1-800-451-4537