Automotive and Tire

Sparks Belting has proven conveyor solutions for automotive and tire applications that will provide significant cost savings and reduce unnecessary downtime.

The automotive industry never sleeps. Sparks Belting understands what it takes to keep you moving.

Sparks understands that 24/7 service is mandatory to service the automotive market, along with reliability, the highest quality products, aggressive pricing, and a proven track record.

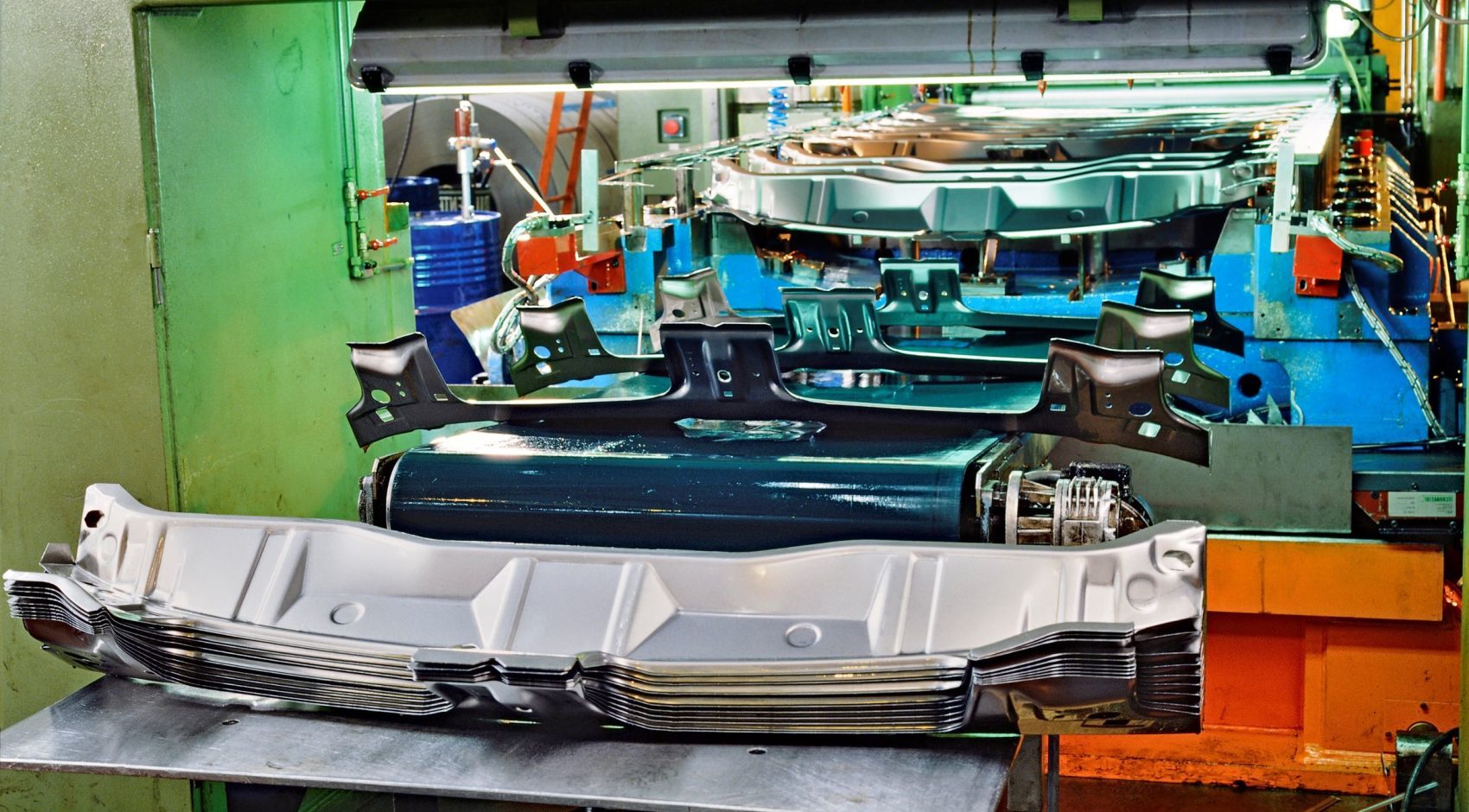

Sharp edges, cutting oils, and continuous wear are the realities faced in today’s stamping plants. Sparks has a long history of providing unique fabrications developed specifically for abrasive applications, the most demanding tracking issues, and a myriad of mechanical splicing challenges.

Learn how to extend the life of an automotive stamping conveyor belt

We offer a wide range of industry leading fabrications which were engineered and developed in house.

Stamping

- Abrasion resistance

- Cutting oils

- Cutting, gouging, sharp objects

- Tracking issues

- Non-marking surfaces

- Product contamination

Rubber Mixing

- High Release

- Wigwag, cutter, and weigh scale belts

- Aggressive surfaces for soap tank

Blanking

- Oil resistant

- Cut resistance

- On-site installations

- Indexing conveyors

Assembly

- Car and people mover heavy belts

- Skid cross-transport belt

- Non-skid pattern

Seats

- Precise tolerances

- Heavy duty loads

- Indexing and pace lines

Tires

- Extruding

- Cutting belts

- Bead forming

- Hugger belts

- Baler conveyors

- Teflon belts for tire transport

We can handle even the toughest challenges.

Excessive Wear/Abrasion

Automotive stamping plants are especially hard on conveyor belts because they tend to wear in predictable patterns. Our Sokitooit Strips allow us to cast urethane in any width and configuration on your belt. Expect substantially longer belt life, less downtime, and significant cost savings.

Splice Failures

The splice is always the weakest part of any belt. Luckily, Sparks is capable of producing unique fabrications specifically customized for your unique challenges. We can address tight transfer points, marking and indentation issues, scratching, or lace pull-out. Sparks can also run tests to determine the optimal size and style of lacing for your unique application.

Tracking Issues

Our cast urethane v-guide has proven time and time again to outlast any tracking guides in the market. Our proprietary blend of urethane provides a superior bond to most belts and will not peel off in a continuous strip.

We combine high quality conveyor system engineering with superior service.

Custom Conveyor Belting and Fabrication

Over 200 standard materials in stock with custom belting available and years of experience supporting food grade and industrial OEM applications.

See All Belting

Dura-Lock Plastic Modular Belting

Our standard materials are FDA approved for direct food contact. Special materials and additives are available for challenging tasks.

Learn More

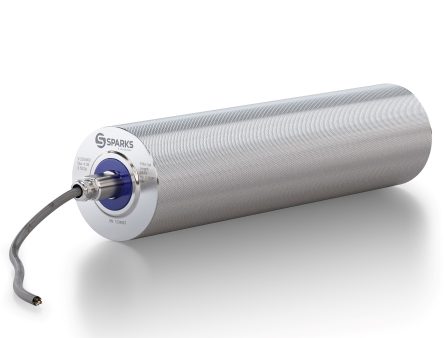

Dura-Drive PLUS Motorized Pulleys

Cost effective, energy efficient, highly sanitary, quiet operation with low maintenance due to its one piece construction. Guaranteed to power your belt conveyors for years.

Learn More

Dura-Tech Timing Belts

Urethane timing belts designed for linear motion, conveying and power transmission applications.

Learn MoreIt's time your automotive conveyor worked for you.

1-800-451-4537